Plastic molding

Many plastic molding applications require precise temperature control. Localized heating with electric heating elements often does not provide the user with enough precision to guarantee product quality. Therefore, the use of heat transfer fluids has become the standard in the industry. Reservoirs, molding machines, and extruders can all be heated to exact temperatures by circulating heat transfer fluid at a controlled rate. The elevated temperatures required and potential problems with corrosion usually prohibit the use of steam because of the relatively small flow passages within the equipment used in the industry. Since Eastman Therminol® heat transfer fluids are noncorrosive and thermally stable when used within their recommended operating temperature ranges, they can be used for nearly all plastic molding applications.

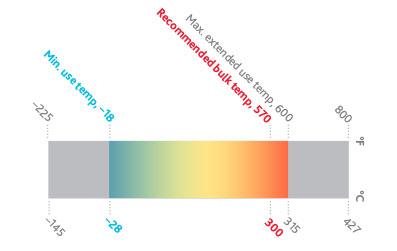

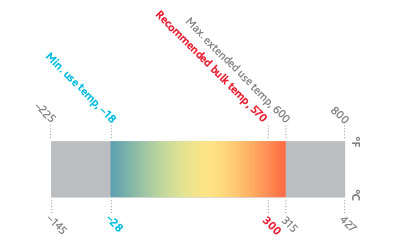

Therminol 55 is a synthetic heat transfer fluid used in moderate-temperature applications. Therminol 55 fluid is designed for use in nonpressurized/low-pressure, indirect heating systems. It delivers efficient, dependable, uniform process heat with no need for high pressures.

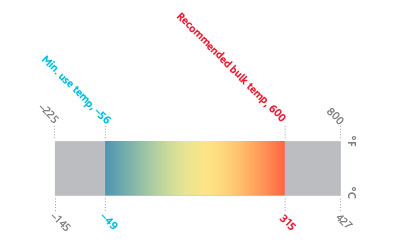

Therminol 59 is a synthetic heat transfer fluid with excellent low temperature pumping characteristics and thermal stability.

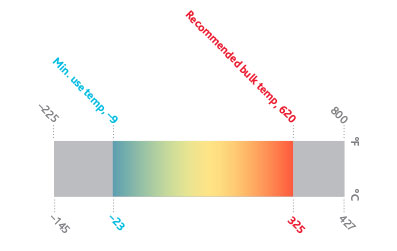

Therminol 62 is a synthetic heat transfer fluid whose chemistry is custom contoured for high-performance, high-purity, low-pressure and exceptional thermal stability.

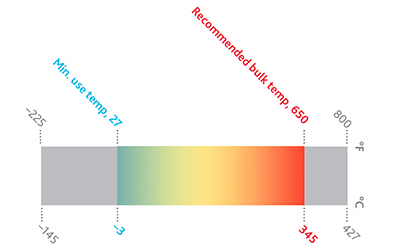

Therminol 66 is the world’s most popular high temperature, liquid-phase heat transfer fluid. Therminol 66 is pumpable at low temperatures, and offers high-temperature thermal stability.

Therminol SP is a synthetic heat transfer fluid used in moderate-temperature applications. Therminol SP fluid is designed for use in nonpressurized/low-pressure, indirect heating systems. It delivers efficient, dependable, uniform process heat with no need for high pressures.