Oil and gas processing

Heat transfer fluid systems are an integral part of the entire system of oil and gas processing. Initial production, transport, refining, and recycling all require the use of heat transfer fluids. Offshore platforms use Therminol liquid-phase heat transfer fluids for facility heating and regeneration of glycols that are used to remove water from the natural gas produced. Refineries use liquid-phase heat transfer fluids to heat reboilers and columns for the distillation of oil and oil-based products. Companies that reprocess and then recycle used lubricating oils use Eastman Therminol® heat transfer fluid in very high-temperature, high-vacuum distillation operations. Pumping stations placed along oil pipelines use heat transfer systems to help control the viscosity of the oil that is moved through the line.

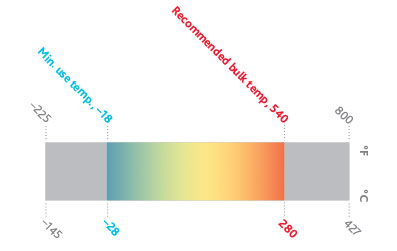

Therminol 54 is a synthetic fluid designed to provide reliable, consistent heat transfer performance over a long service life at maximum bulk temperatures up to 280°C (540°F).

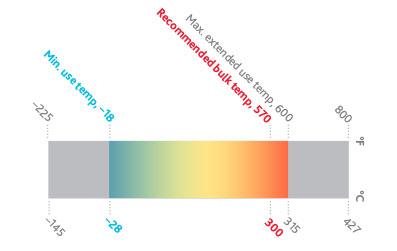

Therminol 55 is a synthetic heat transfer fluid used in moderate-temperature applications. Therminol 55 fluid is designed for use in nonpressurized/low-pressure, indirect heating systems. It delivers efficient, dependable, uniform process heat with no need for high pressures.

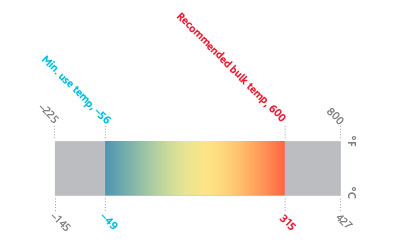

Therminol 59 is a synthetic heat transfer fluid with excellent low temperature pumping characteristics and thermal stability.

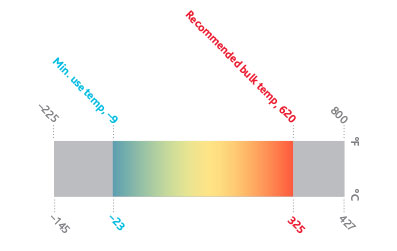

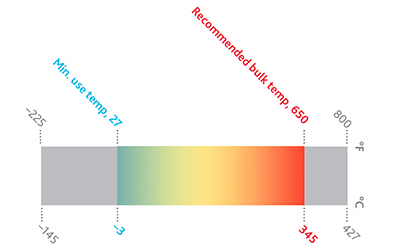

Therminol 62 is a synthetic heat transfer fluid whose chemistry is custom contoured for high-performance, high-purity, low-pressure and exceptional thermal stability.

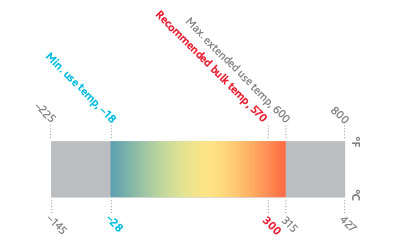

Therminol 66 is the world’s most popular high temperature, liquid-phase heat transfer fluid. Therminol 66 is pumpable at low temperatures, and offers high-temperature thermal stability.

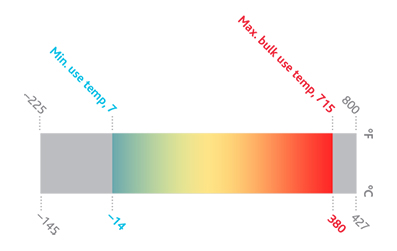

Therminol 72 is an ultra-high temperature liquid phase heat transfer fluid having excellent thermal stability. Therminol 72 was developed for use at temperatures up to 380°C (720°F) in liquid phase heat transfer systems.

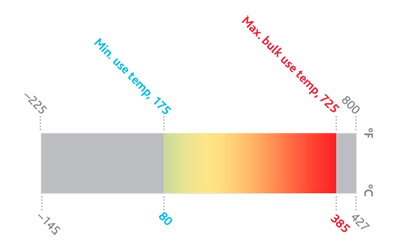

Therminol 75 synthetic heat transfer fluid is a ultra-high temperature liquid phase heat transfer fluid having excellent thermal stability.

Therminol SP is a synthetic heat transfer fluid used in moderate-temperature applications. Therminol SP fluid is designed for use in nonpressurized/low-pressure, indirect heating systems. It delivers efficient, dependable, uniform process heat with no need for high pressures.