Therminol VP-1 heat transfer fluid

Product description

Therminol VP-1 heat transfer fluid is an ultra-high temperature synthetic heat transfer fluid designed to meet the demanding requirements of vapor phase systems or liquid phase systems.

Performance Benefits

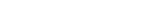

- Superb Heat Transfer Properties—Therminol VP-1 is a synthetic heat transfer fluid which combines exceptional thermal stability and low viscosity for efficient, dependable, uniform performance in a wide optimum use range of 12° to 400°C (54° to 750°F ). Therminol VP-1 has the highest thermal stability of all organic heat transfer fluids.

- Low Viscosity—Therminol VP-1 has a low viscosity to 12°C (54°F). Because of its crystallization point of 12°C (54°F), this fluid may require tracing in colder climates to avoid operational problems.

- Vapor Phase Heat Transfer Fluid—Therminol VP-1 is a eutectic mixture of diphenyl oxide (DPO) and biphenyl. It can be used as a liquid heat transfer fluid or as a boiling-condensing heat transfer medium up to its maximum use temperature. It is miscible and interchangeable (for top-up or design purposes) with other similarly constituted diphenyl-oxide (DPO)/biphenyl fluids.

- Precise Temperature Control—Due to its ability to operate as a vapor-phase heat transfer fluid, Therminol VP-1 is excellent for use in heat transfer fluid systems requiring very precise temperature control.

For more information, visit www.Therminol.com.

Applications

- Adhesives

- Calendar roll heating

- Chemicals & petrochemicals

- Distillation

- Extruding

- Fatty acid

- Fibers

- Formaldehyde

- Gas to liquid (gtl)

- Gas treatment / sweetening / desulpheriz

- HTF - fine chemicals

- HTF - production of bioalcohol

- HTF - production of biodiesel

- Lube oil refining

- Methyl methyl acrylate (mma)

- Polyester (PET)

- Refining

- Resins

- Solar csp

- Specialty and batch chemical production

- Specialty chemicals

- Styrene

- Tall oil

- Terephthalic acid (pta)

- Waste heat recover + orc

Key attributes

- Low Viscosity

- Precise Temperature Control

- Superb Heat Transfer Properties

- Vapor Phase Heat Transfer Fluid

Regulatory information and data sheets

Product availability

Check with local sales office to determine exact availability by country. Orders subjected to minimum order quantity.

Experiencing issues with your system?

Experiencing issues with your system?